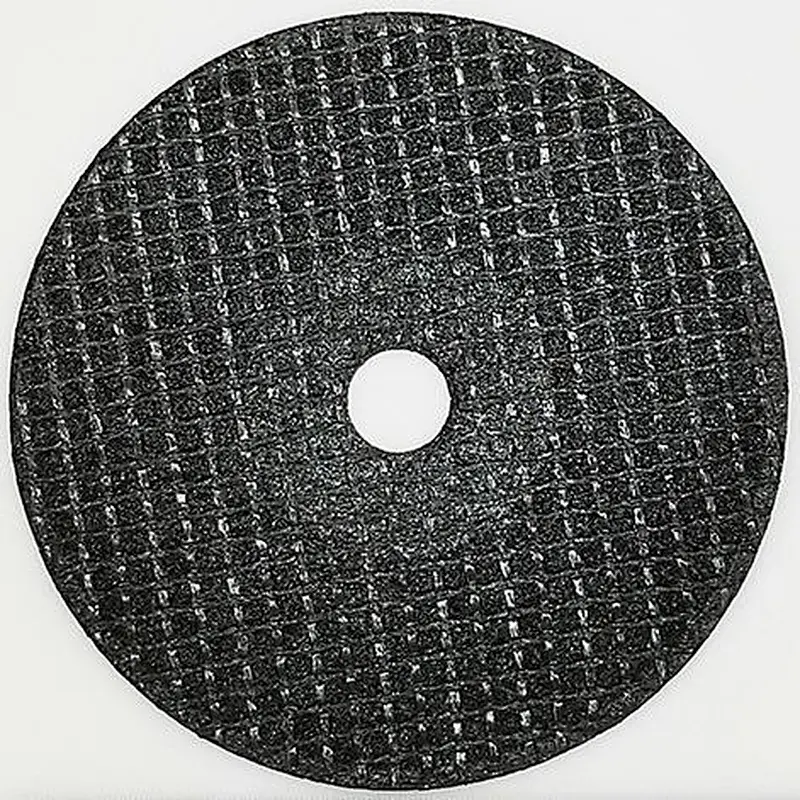

Abrasive: An alumina produced without ferrous, chlorination, or sulfur-containing fillers. – Medium hardness, P multi-purpose tool with high cutting performance and long tool life, reducing the heat generated during cutting.

Select the wheels for your actual application.

For multi – purpose cutting work. Designed for hard-to-reach places.

Suitable for electric and pneumatic direct mill of various output types. It can be used with the cutter rod mounted on the straight tooth grinding machine.

Sizes available range from 50 mm to 75 mm.

Frequently asked questions and solution for cutting wheel:

| Possible Causes | Solution |

| Cutting wheel consumes quickly | |

| Grinding wheel has low hardness | Choose the model with high hardness grade |

| Grinding pressure is too high | Reduce grinding pressure |

| The inner hole of the cutting disc is cracked | |

| The cutting disc is stuck on the work piece | Move forward and backward evenly, and exert pressure along the diametrical direction |

| The cutting disc is used to grinding | A grinding disc is used during the grinding process |

| Too much lateral pressure | Avoid using flange plates with the same inside and outside diameters |

| The inside diameter and the outside diameter are inconsistent | Flange plates of the same diameter are used inside and outside |

| When the grinding wheel is cut, the edge cracks | |

| The diameter of the flange plate is too small | Replace the large diameter flange plate, flange plate diameter generally required to reach 1/3 of the diameter of the abrasion wheel |

| Because the loading pressure of the wheel rim is too large, the wheel rim edge of the grinding wheel is deformed | Adjust flange and grinding wheel pressure to a reasonable level |

| It is used with improper force while cutting | Decrease the load while cutting and reduce the pressure in side direction |

| The diameter of the flange plate is too small | Replace the flange plate with large diameter and generally the diameter of flange plate should be required to reach 1/3 of that of the abrasion wheel |

| The fracture of work pieces is burnt severely | |

| The hardness level of abrasion wheel is over high | Adopt the abrasion wheel of low hardness level and high efficiency |

| The efficiency of the equipment is very low | Replace it with high productivity |

| The belt of the cutting machine is loose | Adjust the belt tightness |

| Grinding wheel hardness is too high | Adopt low hardness, high efficiency grinding wheel |